Thermoplastic Composite Materials

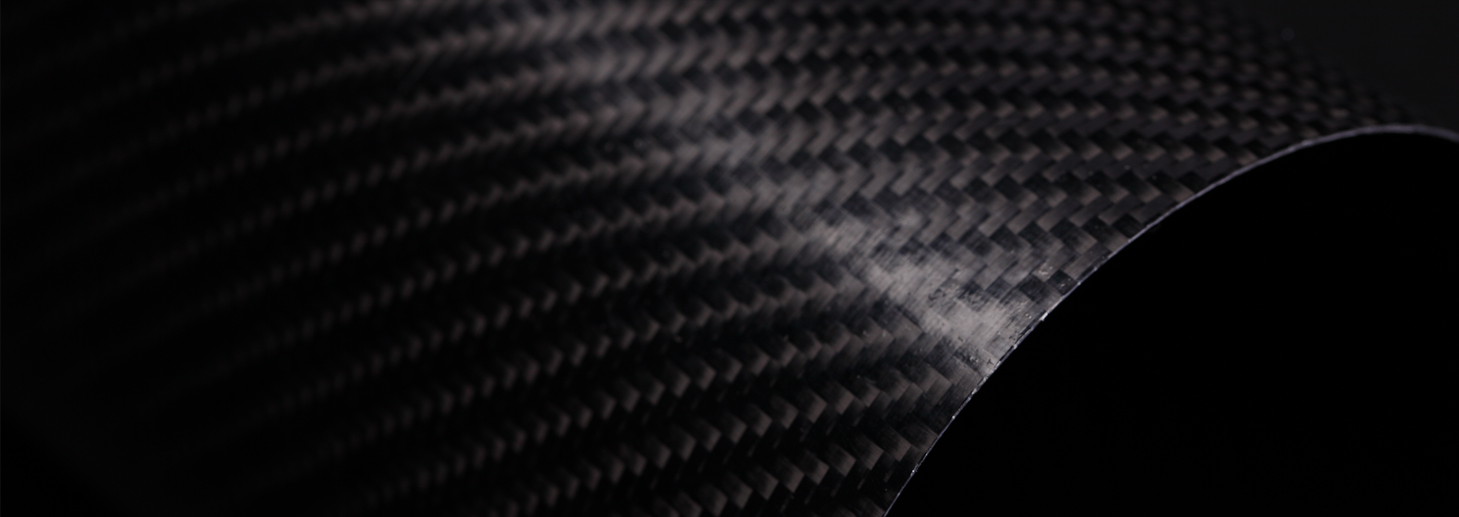

Thermoplastic composite materials use a plastic resin based system, which is combined together with the composite fibers. The most common resins we use are Nylon and TPU, which are combined with carbon fibers or glass fibers, which are already woven together.

The material comes in flat sheets that are semi rigid, we then use a process of heating the material at elevated temperatures, in the range of 200-250 degree Celsius, and forming over a metal mold.

The entire process of heat, forming and cooling has a cycle time of around 2 minutes, thus making the thermoplastic material very suitable for large volume production runs.

The plastic based resin systems in the thermoplastic materials also give the composite material much better impact properties when compared with traditional thermoset resins.

Application :

·shoe inserts, helmet parts

Thermoplastic Composite Materials

HK Office:Unit P,4/f.,Camelpaint Bldg.,Block 3,Hoi Yuen Rd.,Kwun Tong,HK